Aluminum

Aluminium(chemical symbol Al atomic number 13)

Features of aluminum

Aluminum is around 35% the weight of iron making it a light metal and very ductile. It is relatively heat conductive and can also conduct electricity. Pure aluminum is not very strong but aluminum alloys exploit the lightness and workability of aluminum and are used in a variety of products including sheets and molding. The original material is bauxite and it requires a lot of electricity to create aluminum. The properties of aluminum alloys are greatly affected by the type and quantity of their additional elements and there are many varieties of alloys. The most common aluminum alloys are as follows.

Varieties of aluminum and aluminum alloys

1000 type aluminum

These are pure aluminum at 99.00% and above for 1100 and 1200 and at 99.50% and above for 1050. They are excellent for working on and their corrosion resistance but they are not appropriate for construction as they are not strong. They are often used in household products, building materials, electric-transfer parts and electronics.

2000 type alloys

These are Al-Cu. 2017 and 2024 are famous and commonly used thanks to duralumin used in planes. These are as strong as steel. Due to their high amounts of Cu, they are easily corroded so a significant amount of corrosion protection is required in corrosive environments.

3000 type alloys

These are Al-Mn. With the added Mn they maintain the workability and corrosion resistance of pure aluminum while slightly increasing their strength. 3003 is common and is widely used in buildings and containers.

4000 type alloys

These are Al-Si. 4032 controls heat expansion and improves the wear-proof capabilities. By adding miniscule amounts of elements such as Cu, Ni and Mg the heat resistance is increased. These are use in pistons and cylinder heads.

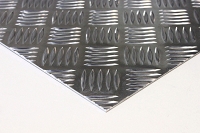

5000 type alloys

These are Al-Mg. This is the most common average-strength alloy, particularly the most common 5052 variety. They are good for corrosion resistance, weldability and moldability. It has particularly high fatigue-strength for its strength and is excellent at resisting seawater.This is used in general sheet metals, ships, cars, buildings, cans and honeycomb cores.

6000 type alloys

These are Al-Mg-Si alloys. These alloys are very strong and resistant to corrosion and are a typical construction material. 6063 is excellent for molding and can be used to produce complicated cross-section configurations. Their use is wide-ranging including building materials, mainly building sash, vehicles and household products.

7000 type alloys

These are Al-Zn alloys. These can be categorized into the strongest of aluminums, Al-Zn-Mg-Cu type alloys, and those without Cu, Al-Zn-Mg-Cu alloys. The typical Al-Zn-Mg-Cu type alloy is 7075 and is used in planes and ski poles.

Reference:Aluminum Handbag

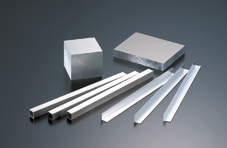

Aluminum cut sheets

We also prepare a wide range of cut sheets outside of the set sizes.

A5052P

Al-Mg type, non-heat-treatable alloys

These are the most representative medium-strength alloys and are resistant to corrosion and good for welding and molding. Their fatigue limit is high for their strength and they are very good at resisting sea water.

ALHIGHCE-III

This is the most deluxe brand product of Kobe Steel, an A5025 cut sheet A1-Mg non-heat-treatable alloy. On top of the A5052 features, it takes the residual stress to the limit and next to no dents are found after machining.

HOME

HOME

Preceding page

Preceding page